Load Factor (LF)

The transportation and logistics sector is vital to the global economy, seamlessly connecting suppliers, manufacturers, and consumers across countries and continents. However, efficiency in logistics operations isn’t achieved by merely moving goods from point A to point B. In reality, maximizing resources, minimizing operational costs, and improving profitability depend heavily on a key metric known as the Load Factor (LF). This indicator not only measures efficiency in cargo handling but also offers insights into the financial health and environmental impact of logistics operations. In this article, we’ll explore what load factor is, how it’s calculated, and why it plays such a significant role in the transportation and logistics industry.

Introduction to Load Factor in Transportation and Logistics

Load Factor (LF) is a term widely used across various industries, particularly in transportation, where it serves as a measure of efficiency. In the logistics sector, load factor is defined as the ratio of actual cargo (freight or passengers) carried compared to the total capacity available. It provides an insight into how effectively transportation resources are being utilized. For a business focused on profitability and sustainability, increasing the load factor is critical.

Simply put, load factor determines how much of the available capacity is actually being used, reflecting how well assets are managed within the transportation and logistics sector.

Understanding the Importance of Load Factor

In logistics, efficiency is often the name of the game. High load factors suggest that a transport vehicle—whether a truck, airplane, or ship is carrying close to its full capacity, thus generating optimal revenue per trip. Conversely, a low load factor indicates unused capacity, translating to lost revenue opportunities and increased costs per unit transported. Let’s break down why this metric is so critical:

Operational EfficiencyA high load factor is a direct indicator of operational efficiency, reflecting the ability to maximize resources while minimizing waste.

Cost ManagementFuel costs, labor expenses, and maintenance are constant, irrespective of load. A higher load factor lowers the cost per unit transported, helping maintain profitability.

Environmental ImpactEfficient load management reduces the number of trips, which helps reduce fuel consumption and carbon emissions, contributing to sustainable practices.

Customer SatisfactionTimely, efficient transportation often results in faster delivery times and lower shipping costs, enhancing customer satisfaction and competitive advantage.

How to Calculate Load Factor in Logistics

Calculating load factor in the transportation and logistics sector is relatively straightforward. For logistics providers, the load factor is typically measured by comparing the actual cargo weight or volume with the total capacity of the transport vehicle.

Formula for Load Factor Calculation

In freight logistics, the load factor (LF) is calculated using this formula:

Load Factor (%) = (Actual Load / Maximum Capacity) x 100

Let’s look at a practical example. If a freight truck has a maximum capacity of 20,000 pounds and is currently carrying 15,000 pounds of cargo, the load factor would be:

Load Factor = (15,000 / 20,000) x 100 = 75%

This indicates that 75% of the truck’s carrying capacity is being utilized, leaving a 25% idle capacity that could potentially be filled to improve operational efficiency.

1. FedEx Corporation

Industry Segment: Package and Freight Delivery

Focus: Maximizing cargo weight utilization on delivery trucks to reduce operational costs.

Example Calculation

Suppose FedEx operates a truck with a maximum capacity of 20,000 pounds on a daily route. On a particular day, the truck is loaded with 16,000 pounds of parcels.

The load factor (LF) is calculated as:

This 80% load factor shows FedEx is using 80% of the truck’s capacity. To improve, FedEx may consolidate shipments or adjust the route, aiming for at least a 90% load factor on each truck to minimize per-unit delivery cost.

2. United Airlines

Industry Segment: Passenger and Cargo Airline

Focus: Optimizing passenger and cargo load on flights.

Example Calculation

Suppose United Airlines operates a flight with a total seating capacity of 200 passengers and has 175 booked seats on a given flight. The load factor (LF) for passengers is:

In addition, if the flight has a cargo hold capacity of 10,000 pounds but is only carrying 8,500 pounds of cargo, then:

United Airlines targets load factors around 85% or higher for both passengers and cargo to maintain profitability per flight. This balance helps them optimize revenue across passenger and cargo segments.

3. DHL Express

Industry Segment: International Logistics and Courier ServicesFocus: Maximizing air cargo space on international routes.

Example Calculation

DHL Express operates an international flight with a maximum cargo volume of 500 cubic meters. On a specific route, they fill 450 cubic meters with packages and goods.

The volume load factor (LF) is:

A 90% volume load factor indicates efficient use of space. To reach an optimal load factor close to 100%, DHL may adjust cargo distribution or pricing to maximize air cargo usage.

4. Maersk Line

Industry Segment: Shipping and Maritime Logistics

Focus: Optimizing container load on shipping vessels.

Example Calculation

A Maersk container ship has a maximum capacity of 18,000 TEUs (Twenty-foot Equivalent Units) and is loaded with 15,300 TEUs for a particular route.

The load factor (LF) in terms of TEU capacity is:

With an 85% load factor, Maersk optimizes container load while ensuring cost-efficiency. Reaching closer to 90-95% is ideal, balancing revenue with operational efficiency without risking delays from overloading.

5. Union Pacific Railroad

Industry Segment: Freight Railroad TransportationFocus: Maximizing freight weight on trains to optimize trips.

Example Calculation

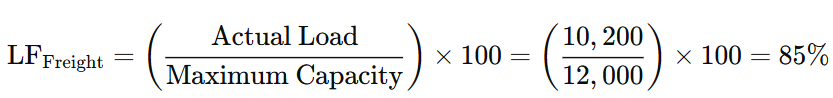

Suppose a Union Pacific freight train can carry a maximum load of 12,000 tons on a given line, and it is loaded with 10,200 tons of cargo on a trip.

The load factor (LF) based on cargo weight is calculated as:

An 85% load factor ensures a profitable journey without exceeding load limits, maintaining safety standards and efficiency. Union Pacific aims to achieve load factors around 85-90% to maximize operational returns without compromising on schedule and maintenance needs.

Types of Load Factor in the Transportation Sector

In the logistics and transportation industry, load factor can be categorized into different types based on how it is measured:

Weight Load Factor: Measures the actual weight carried against the maximum weight capacity.

Volume Load Factor: Assesses the space occupied by cargo relative to the total available space.

Revenue Load Factor: Typically applied in passenger transportation, comparing revenue-generating capacity utilization against total capacity.

Factors Affecting Load Factor in Logistics

While load factor is a key metric for efficiency, it is also influenced by a variety of internal and external factors. These factors include:

Route and DistanceShorter distances might result in lower load factors due to limited cargo consolidation opportunities, whereas longer routes often support higher load factors.

Demand FluctuationsPeak seasons, such as holiday shopping periods, may lead to higher load factors due to increased demand, while off-peak periods might experience low load factors.

Vehicle Size and TypeThe choice of vehicle type and size significantly affects load factor, as certain vehicles are better suited to certain cargo types (e.g., perishable goods, heavy equipment).

Fuel Prices and Economic ConditionsHigher fuel costs might push logistics providers to increase load factors to cut costs, while economic downturns could lead to reduced cargo volumes and lower load factors.

Customer RequirementsCustomer demands for faster deliveries can affect load factor as logistics companies may be forced to transport goods with less-than-optimal loads to meet timelines.

Impact of Load Factor on Profitability

The load factor is closely tied to profitability in logistics operations. A high load factor indicates better asset utilization, which directly translates to reduced operational costs and increased profit margins. In addition:

Economies of ScaleLogistics providers benefit from economies of scale when load factors are maximized, meaning the cost per unit decreases as more units are transported in a single trip.

Reduced Cost Per MileA higher load factor reduces the cost per mile, which is one of the most critical operational metrics in logistics. Each extra pound of cargo or cubic foot filled reduces the per-unit cost.

Fixed Costs OptimizationSince fixed costs, such as vehicle depreciation and labor, remain constant regardless of cargo volume, higher load factors make it easier to cover these costs and increase profitability.

Strategies to Improve Load Factor in Logistics

Improving load factor can significantly enhance the profitability and sustainability of a logistics business. Here are some effective strategies:

Route OptimizationUsing advanced route optimization software can help reduce unnecessary mileage, improve load consolidation, and increase load factor.

Dynamic PricingOffering discounted rates during low-demand periods can encourage customers to ship more goods, helping to maintain a high load factor year-round.

Freight ConsolidationCombining shipments from multiple customers or consolidating smaller loads into larger shipments can lead to a higher load factor, especially for less-than-truckload (LTL) operators.

Adopting Digital PlatformsDigital logistics platforms enable better visibility and tracking, helping logistics providers plan and adjust loads dynamically to achieve a higher load factor.

Inventory Pooling and Demand ForecastingBy sharing inventory data with customers and forecasting demand accurately, logistics providers can preemptively plan for high load factor shipments.

Challenges in Managing Load Factor

While improving load factor is essential, achieving optimal levels can be challenging. Some of the common challenges logistics providers face include:

Demand VolatilityVariations in demand can lead to inconsistency in load factors, making it challenging to plan and optimize load capacity.

Complexity in Multi-Stop RoutesRoutes involving multiple stops require efficient load planning, as partial unloading can lead to decreased load factors mid-route.

Cargo Type and CompatibilityDifferent cargo types may not be compatible with one another, limiting opportunities for load consolidation and resulting in lower load factors.

Balancing Speed and EfficiencyIn some cases, faster delivery requirements might necessitate trips with lower load factors, prioritizing customer satisfaction over operational efficiency.

The Future of Load Factor in Transportation and Logistics

With advancements in technology, logistics companies are increasingly equipped to optimize load factors and make data-driven decisions. The integration of AI, IoT, and machine learning in logistics has made it possible to track, analyze, and predict demand and load factors more accurately. Future trends that could impact load factor management include:

AI-Driven Load OptimizationAI algorithms can analyze historical data to predict load patterns, enabling logistics providers to optimize capacity utilization dynamically.

Blockchain for Load TransparencyBlockchain technology can provide end-to-end transparency, ensuring optimal load allocation by allowing shippers to match their needs with logistics providers in real-time.

Electric Vehicles and Sustainability FocusAs logistics companies adopt electric vehicles, which typically have lower operating costs, the focus on maintaining high load factors could intensify to maximize returns on green investments.

Load Factor (LF) vs Other Metric

Load Factor (LF) vs. Capacity Utilization

Both Load Factor and Capacity Utilization assess how well transportation resources are used, but there’s a subtle difference:

Load Factor measures the percentage of a vehicle's or vessel’s capacity that’s actually being used based on the weight, volume, or passenger count of what it’s carrying.

Capacity Utilization usually looks at the broader picture across a fleet or facility, evaluating how much of the total available capacity is used over a certain time frame.

For example, if a freight company has a fleet of 50 trucks, each with a maximum capacity of 10 tons, capacity utilization will tell us how much of the fleet’s collective capacity is being used on average. In contrast, LF might focus on individual trucks within the fleet and measure how efficiently each one is filled.

Summary: Load Factor zooms in on vehicle-specific utilization, while Capacity Utilization provides an overall snapshot of resource use across a fleet or facility.

Load Factor (LF) vs. Yield

In logistics, Yield measures revenue generated per unit of cargo weight, volume, or distance. While LF looks at how well a vehicle’s space is used, Yield focuses on the financial return from that usage.

For instance, an airline might have an 85% passenger load factor on a flight, but if most tickets were sold at a discount, the yield might be low. Conversely, a high-yield flight with premium pricing could still have a lower load factor if some seats are left empty. This shows that LF alone doesn’t tell the whole financial story Yield captures the revenue efficiency of the space being used.

Summary: Load Factor shows operational efficiency, while Yield shows revenue efficiency.

Load Factor (LF) vs. Average Haul Length

Average Haul Length refers to the average distance over which goods or passengers are transported. When analyzed together with LF, it offers insight into how efficiently long-haul routes use capacity.

For instance, a logistics company might have a high load factor on short routes because those are easier to fill, but long-haul routes with a lower LF could point to missed opportunities for higher-margin cargo consolidation. If a company is running long routes with a low LF, it could be losing out on profitability since those routes typically involve higher costs.

Summary: Load Factor shows space efficiency, while Average Haul Length helps gauge cost-efficiency across varying route distances.

Load Factor (LF) vs. Empty Miles (Deadhead)

Empty Miles (also called Deadhead) refers to the percentage of miles driven without any load. It’s a key efficiency metric for trucking companies, as empty miles generate no revenue but still incur costs like fuel, driver wages, and maintenance.

A high load factor is an indicator of filled trips, but if a truck’s route still has empty return trips, then empty miles remain high. For instance, a truck might achieve a 90% load factor on a delivery, but if it returns empty, the total efficiency of the trip drops. Minimizing empty miles is as crucial as maximizing LF because they directly affect profitability and environmental sustainability.

Summary: Load Factor measures load capacity on filled trips, while Empty Miles assesses efficiency by reducing non-revenue-generating trips.

Load Factor (LF) vs. On-Time Performance

While Load Factor focuses on how full each trip is, On-Time Performance (OTP) measures how reliably deliveries arrive according to schedule. High LF and OTP are both desired, but there can be trade-offs between them.

For example, a trucking company might delay a delivery to maximize load factor on a truck, but that delay could hurt OTP if the shipment doesn’t arrive as scheduled. Balancing LF with OTP requires strong demand forecasting and scheduling to ensure full loads while maintaining reliability for customers.

Summary: Load Factor prioritizes efficiency per trip, while On-Time Performance emphasizes reliability and customer satisfaction.

Load Factor (LF) vs. Cost per Mile

Cost per Mile is a comprehensive measure of the expense incurred for every mile traveled by a vehicle, factoring in fuel, labor, and maintenance. A higher LF usually reduces the Cost per Mile since more cargo or passengers can be transported per mile driven, effectively lowering the cost per unit carried.

Imagine a delivery truck with a low load factor traveling 100 miles with high fuel costs and minimal cargo. This increases the cost per mile and makes the trip less profitable. By maximizing LF, companies reduce the average cost per mile, translating to better financial outcomes.

Summary: Load Factor boosts efficiency by maximizing vehicle use, directly lowering Cost per Mile and enhancing profitability.

FAQs

What is load factor in logistics?

Load factor in logistics measures the actual cargo carried compared to the maximum capacity of the transport vehicle, indicating efficiency.

Why is load factor important in logistics?

A higher load factor means more efficient use of transport capacity, reducing costs and enhancing profitability.

How is load factor calculated in transportation?

Load factor is calculated by dividing the actual load by the maximum capacity and multiplying by 100.

How can logistics companies improve load factor?

Strategies include route optimization, freight consolidation, dynamic pricing, and demand forecasting.

What affects load factor in the transportation sector?

Factors include route length, vehicle type, demand fluctuations, and customer requirements.

What role does load factor play in sustainability?

By maximizing load factor, logistics companies reduce the number of trips, thereby lowering fuel consumption and emissions.

Conclusion

The load factor is an indispensable metric in the transportation and logistics sector, serving as a barometer for efficiency, cost management, and environmental responsibility. As logistics companies aim to operate sustainably and profitably, optimizing load factor will remain at the forefront of industry best practices. Leveraging technology, forecasting demand, and engaging in strategic load management will enable businesses to navigate the challenges of the ever-evolving logistics landscape while maintaining a strong focus on efficiency and sustainability.

-min.png)

-min.png)

Comments